Bio-Energy, Ethanol & Waste-to-Energy Project Experience

Pioneer Chem Solutions has been associated with ENA , Ethanol Plants , Captive Power, CBG, Ethyl Acetate, Hydrogen and ZLD , Incineration Boiler and Zero Liquid and Renewable Energy Projects Across India and Overseas. These projects reflect strong engineering involvement, execution support and long-term operational engagement.

ONGOING BIO-ENERGY & ETHANOL PROJECTS

Large-scale ethanol and integrated bio-energy projects currently under execution and construction across India and international locations.

60 KLPD grain-based ethanol plant integrated with bio-methanation systems. Project executed under EPC & PMC scope and currently under execution.

510 KLPD large-scale ethanol facility with boiler and ZLD integration. Engineering and PMC services for cane syrup and molasses-based operations.

300 KLPD grain-based ethanol plant developed with PMC and engineering support. Project is progressing with focus on efficiency and scalability.

200 KLPD ethanol plant with integrated ZLD system using cane syrup feedstock. Project supported under EPC scope and currently in ordering stage.

COMPLETED ETHANOL & DISTILLERY PROJECTS

Successfully commissioned ethanol and distillery projects delivering stable operations, regulatory compliance and long-term reliability.

65 KLPD grain-based ethanol plant delivered under turnkey PMC model. Successfully commissioned with stable plant operations.

220 KLPD molasses-based distillery supported through engineering and O&M. Plant operating with consistent performance and compliance.

60 KLPD molasses-based distillery managed under full project management scope. Executed with focus on schedule and operational readiness.

20 KLPD molasses-based distillery supported through EPC assistance. Project completed with efficient commissioning support.

50 KLPD molasses-based distillery delivered with engineering and commissioning services. Designed for reliable production and compliance.

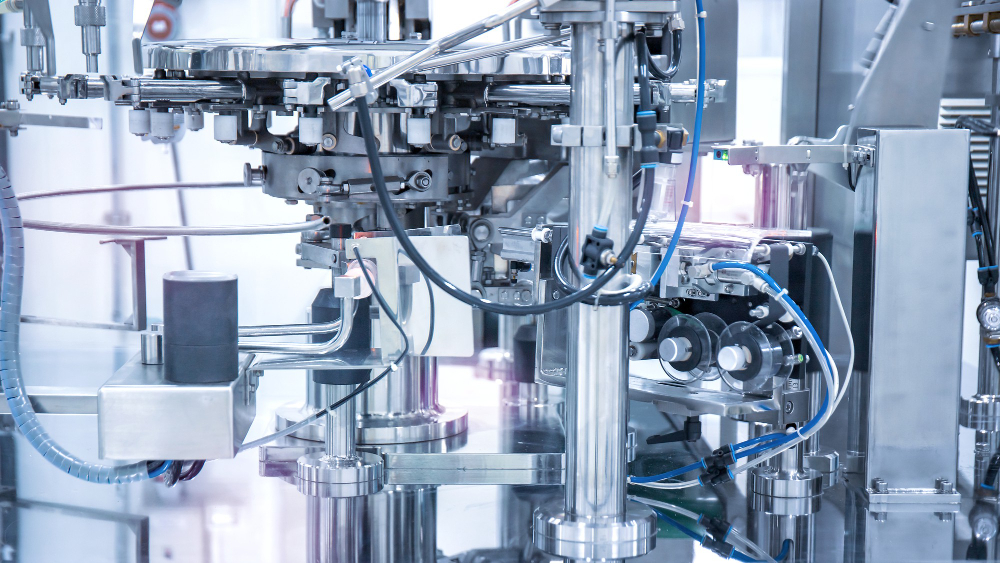

ZLD, BIOGAS & WASTE-TO-ENERGY PROJECTS

Environmental and resource recovery systems designed for zero liquid discharge, biogas generation and sustainable waste management.

600 KLPD spent wash evaporation system engineered for ZLD compliance. High-capacity design for industrial effluent handling.

Bio-methanated evaporation system with 450 m³/day capacity. Executed under EPC scope including commissioning support.

Molecular sieve and purification system revamp project. Scope included revamp execution and start-up support.

400 m³ MEE plant supported through technical consultancy services. Focused on process efficiency and operational reliability.

50 KLPD molasses-based distillery delivered with engineering and commissioning services. Designed for reliable production and compliance.

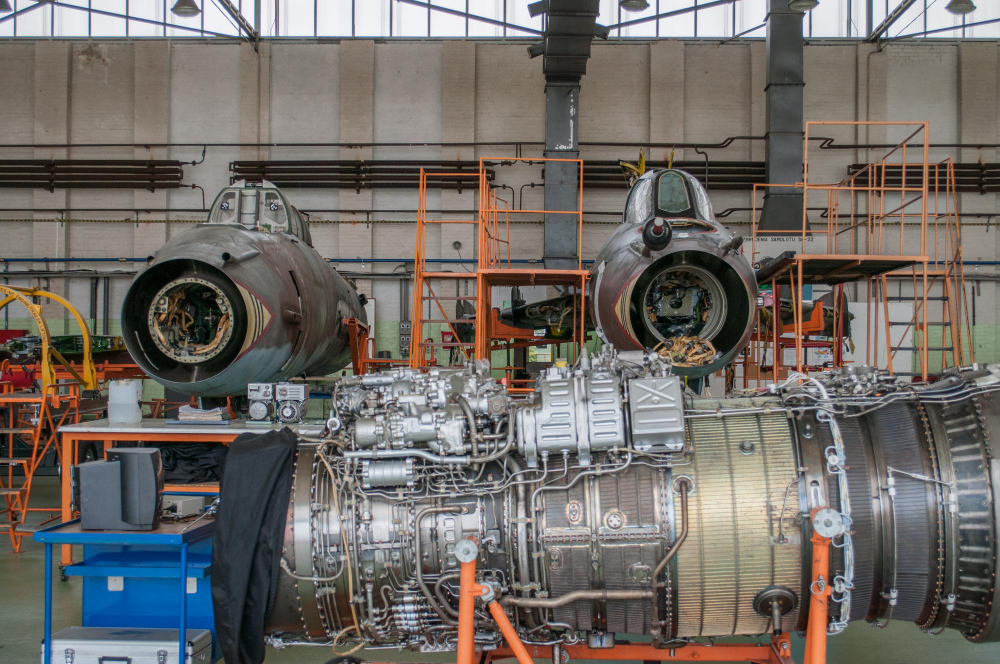

INCINERATION BOILERS & POWER PLANTS

Energy recovery solutions utilizing industrial waste streams for steam generation and power production.

80 TPH incineration boiler generating 8 MW power using spent wash. Integrated solution for sustainable energy recovery.

45 TPH boiler system operating on slop and biomass fuels. Designed for efficient waste utilization.

22.5 TPH boiler system using coal and bagasse as fuel. Supports stable steam generation for plant operations.

Molecular sieve and purification system revamp project. Scope included revamp execution and start-up support.

OPERATION & MAINTENANCE (O&M) PROJECTS

Long-term operational responsibility covering plant operation, manpower deployment and performance management.

65 KLPD distillery operated with 66 personnel. O&M services ongoing since 2018.

220 KLPD distillery supported under O&M services. Operational responsibility since 2020.

110 KLPD plant managed with 58 skilled professionals. Consistent operations maintained since 2019.

120 KLPD distillery operated under full O&M scope. Operations supported since 2020.

What they say about us

Semper aliquet primis venenatis platea viverra magna praesent sed mattis netus nostra.

End-to-end engineering and EPC expertise delivering reliable, efficient, and sustainable industrial solutions worldwide.